Samples of more than 40 FSO/FPSO Projects

Offshore Oil & Gas

Tango FLNG and Excalibur FSU

Fast-track conversion of an LNGC to an FSU and arrangement for interconnection to an FLNG barge to create an integrated offshore ship-to-ship LNG export terminal for Eni Congo.

ICE’s scope of work: Onboard survey including laser scanning, basic design, MTO, detail design, yard supervision, inclining tests, various Class and regulatory matters, etc.

Client: Exmar, Belgium

Shipyard: Drydocks World, Dubai.

Year: 2022-24

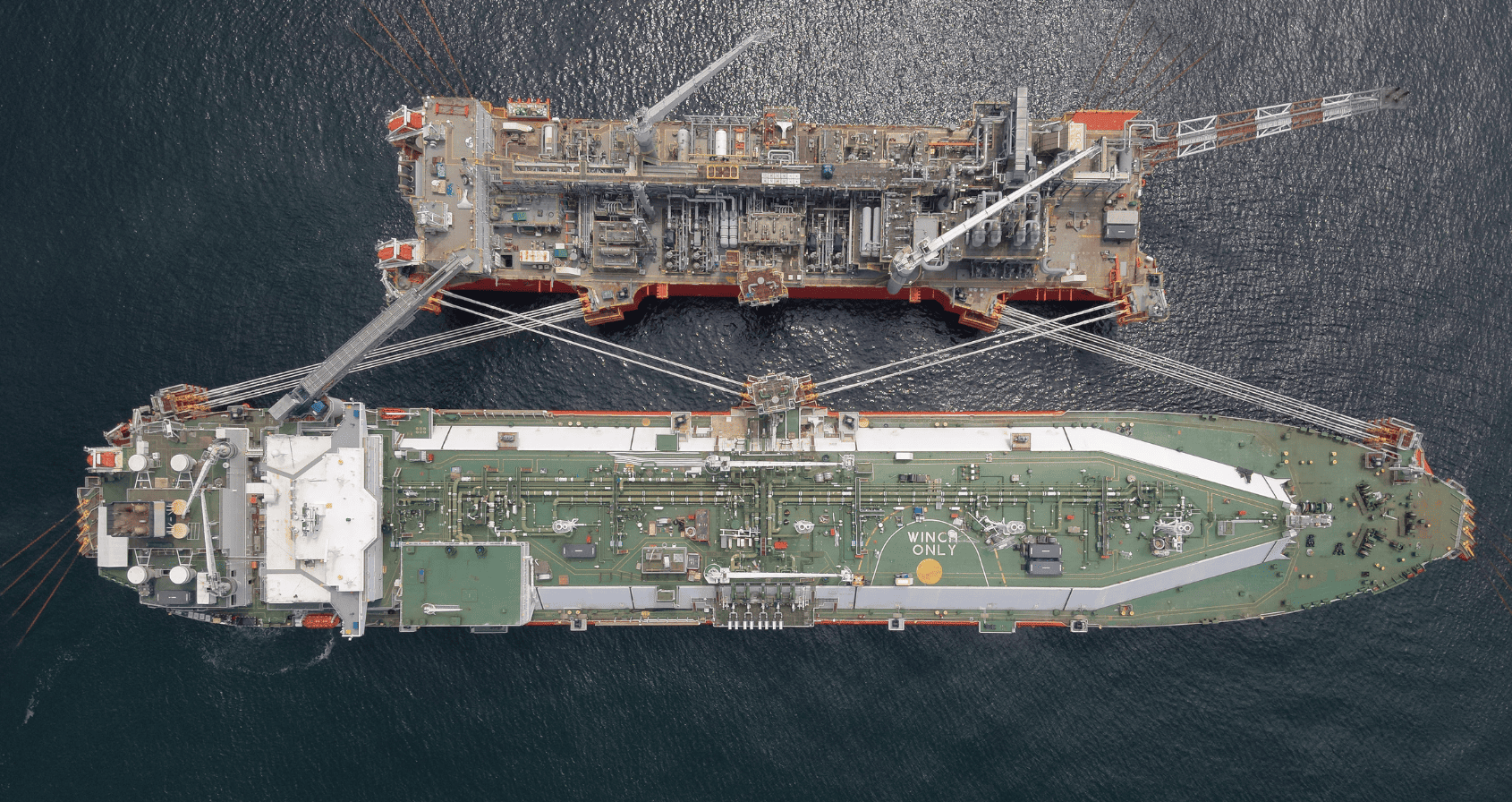

Martin Linge B FSO

Conversion of “Hanne Knutsen” Shuttle Tanker into a Floating Storage and Offloading (FSO) Unit

ICE’s scope of work:

– Front end engineering & design (FEED) study,

– Detail engineering for Class approval,

– Development of AVEVA 3-D model,

– Process engineering,

– Procurement engineering,

– Fabrication and construction engineering of the conversion.

ICE’s scope of work covered all hull and topside engineering for disciplines:

– Technical safety & HSE,

– Corrosion / Cathodic protection,

– Naval architecture,

– Structure, architectural and hull outfitting,

– HVAC,

– Marine & process,

– Mechanical,

– Piping and layout,

– Electrical,

– Instrumentation and telecom.

Client/Shipyard: KNOT FSO 1 AS, Norway / Remontowa Shiprepair Yard, Gdańsk, Poland

Owner/Operator: Total E&P Norge’s Martin Linge Development on the Norwegian Continental Shelf

Year: 2012 & 2013 – 2017

Ondina

Drill Ship Newbuild

ICE’s scope of work: Update and completion of Class package, detail design, assist with procurement of equipment, and generate production information for a series of six deep water drill ships to be built in Japan and Brazil.

Client/Shipyard: Enseada Indústria Naval & Kawasaki Heavy Industries, Ltd (Sakaide and Kobe shipyards)

Owner/Operator: Sete Brasil S.A

Year: 2012 -14

OSX-2

Floating Production Storage and Offloading (“FPSO”) Vessel

ICE’s scope of work: Marine systems conversion.

Client/Shipyard: SBM Monaco / Keppel Shipyard, Singapore

Owner/Operator: OSX Brasil S.A

Year: 2011 -12

Falcon Spirit

Conversion of “Sarita” Shuttle Tanker into a Floating Storage and Offloading (FSO) Unit

ICE’s scope of work: Basic and detail design for conversion of a shuttle tanker to an FSO for deployment on the Al Rayyan field off the coast of Qatar. Detail engineering for Class approval and fabrication and construction engineering.

ICE’s scope of work covered disciplines:

– Naval Architecture,

– Structural,

– Piping,

– Electrical.

Class: DNV-GL

Client/Shipyard: Teekay, Norway / Drydocks World Dubai

Owner/Operator: Teekay Offshore Partners / Occidental Qatar Energy Company LLC

Year: 2009

Gimboa FPSO

Conversion of “T/T Magdelaine” Oil Tanker into a Floating Production Storage and Offloading (“FPSO”) Vessel Conversion

ICE’s scope of work: Basic design including structural analyses and Class approvals, detail engineering and shipyard troubleshooting assistance for conversion of a VLCC to an FPSO for service offshore Angola.

Client/Shipyard: Saipem/Moss Maritime Drydocks World Dubai

Owner/Operator: Saipem

Year: 2006 -07

Cidade de Vitoria FPSO

Conversion of “Margaux” VLCC into a Floating Production Storage and Offloading (“FPSO”) Vessel

ICE’s scope of work: Full scope of marine conversion basic design including pre-conversion inspection of VLCC, structural design including extensive FEM analyses, addition of generating capacity, addition of accommodation and heliport, calculation and design of topside support structures, safety analyses, integration of topside and marine systems, addition of offloading and spread mooring systems, arrangement of riser support structures, all related Class (ABS) submissions and shipyard trouble-shooting assistance in Dubai.

Client/Shipyard: Saipem / Drydocks World Dubai

Owner/Operator: Saipem/Petrobras

Year: 2005